Spreaders

Hi Rick,

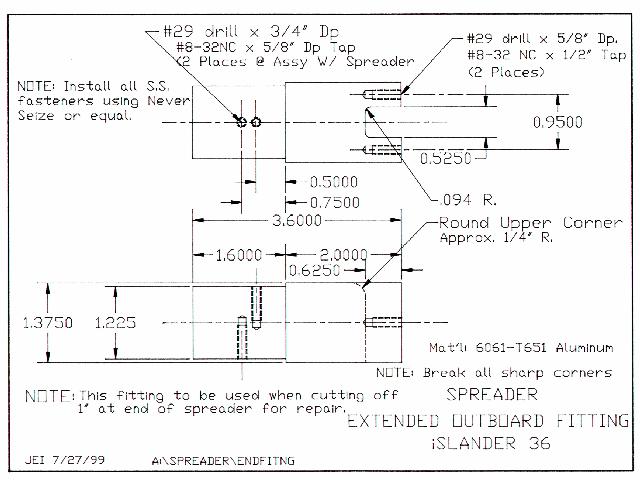

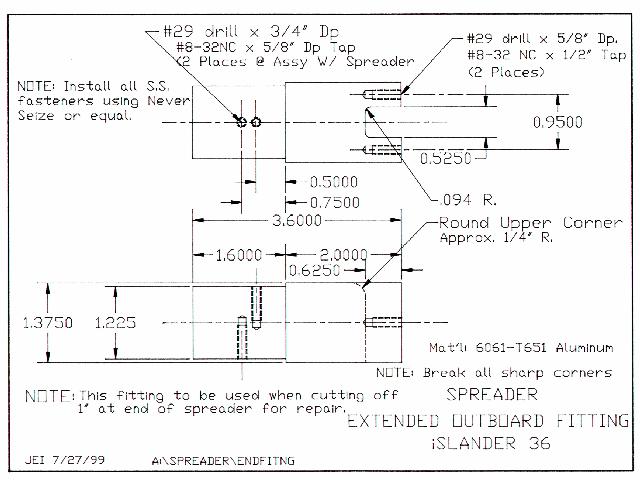

While sailing our 1972 Islander 36 last week, one of our lower spreader boots came off and fell on deck. While going forward to retrieve the boot, I found pieces of corroded aluminum on the deck. Today I removed the upper and intermediate shrouds (after replacing their function with the main and spinnaker halyards) and took the lower spreaders off of the mast. I found that the outboard fitting on both spreaders were mostly white powder which broke up without much effort. During this corrosion process there must have been quite a bit of swelling which bell mouthed the end of the spreader to the point where they were cracked back about one inch. I have two possible solutions. See Picture # 1.

1. Try to reshape the end and MIG weld the cracks. Then make two new end fittings out of 5000 series aluminum Identical to those that died. (Not too good of a solution, but possible)

2. Cut one inch off of the outboard end of each spreader and make new end fittings which are one inch longer and extend one inch farther into the outboard end of the spreaders.(I like this one best.)

Since the outboard end fittings were in such bad shape, I can't tell if the fittings are intended to be loose on the shrouds or actually clamp the wires. So I would like comments on this also.

I would like any comments on the above and also any alternate solutions that any members may have.

By the way, the upper spreaders are another story and I will not go up there until I solve the lower spreader problem. Who would want to go up a mast cantilevered off of the lower shrouds only. Not me!!

I'll let you know how things work out.

Thanks for your help and comments.

John Isakson jisakson@whidbey.net

Camano Island, WA

From:

Steve Olsen olsen@halcyon.com

Date: 07/26/99 03:24:16 PM GMT

When we re-powered in '96, we had the crane pull the mast out for inspection, repainting & rewiring. We found the same condition you describe. We had the corroded spreader welded & replaced upper & lower shroud fittings. The problem was caused by the ss shrouds passing through aluminum fittings without some barrier to keep the different metals from touching. I suspect that every Islander has a similar problem.

I don't think you can do this with your mast in place. You'll have to pull it - a 1972 (like ours) should be due for a thorough rigging exam anyway. When you do this, check out the mast step. We found ours (& the base of the mast) badly corroded. We cut 3/4" off the bottom of the mast & had a thicker mast step manufactured. We also found that the pin attaching theforestay to the mast had been working at the mast fitting.

All of the work was done in Port Townsend by PT Rigging not far from you. Our old Palmer is still there if you need parts. You're welcome to check out our boat in Kingston any time.

Steve Olsen

From:

John Isakson jisakson@whidbey.net

Date: 07/27/99 04:30:52 AM GMT

Thanks Rick for sending my request throughout the group and as you can see, the system works.

John Isakson

Thanks Steve,

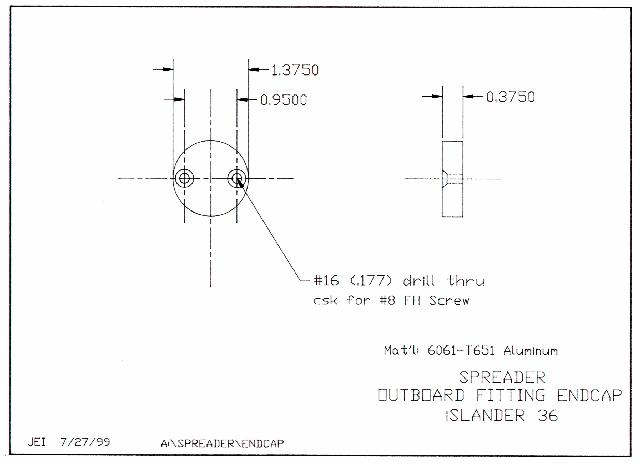

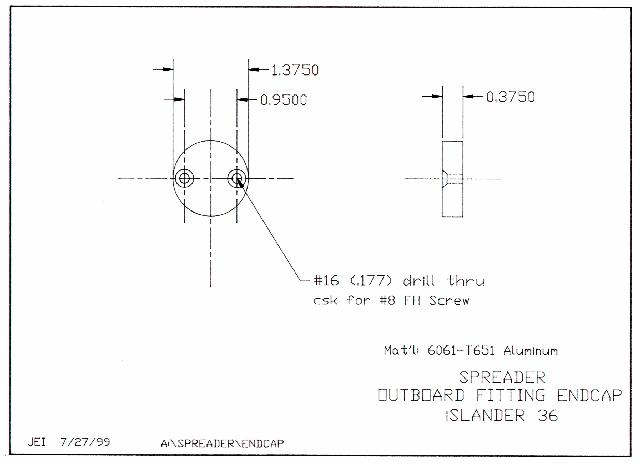

Your comments were very helpful. The outboard end of both spreaders are so bad that I am going to cut them off. I picked up a round bar of 6061 T651 aluminum at Skagit River Steel today and will turn and mill new end fittings 1" longer than the old fittings to compensate for cutting off 1" from the spreader. Next year I plan to pull the mast and check all of the rigging so your advice is well taken.

The last time I pulled the mast, I found the same mast step condition that you did. I think that the mast step and lower end of the mast were sacrificial to the steel base which is also the backing plate for the keel. The steel base was so protected that you could still see the mill marks left from the manufacture of the steel plate. I also cut 1" off of the bottom of the mast. I got a new mast step fitting and a 1" thick piece of 5000 series aluminum to place under the mast step to make up for the 1" cut off the mast. I coated both the mast step and the 1" aluminum spacer with zinc chromate primer and placed a sheet of mylar (an old engineering drawing) under the spacer to isolate the aluminum from the steel. The stainless bolts still go through both but I can't do anything about that.

It was interesting how we got into the situation where pulling the mast was necessary. We were returning from north of Desolation Sound and were beating down Trincomali Channel in the Gulf Islands when we heard a "thump" like we had hit a log, but we saw no log. So we continued beating down to Montague Harbor where we dropped the sails and anchored. Sitting back with wine glass in hand, Delores and I both noticed all the shrouds were flopping back and forth. the next morning I tightened the turnbuckles and we continued home. Needless to say, after the mast was pulled, we discovered we had crushed the corroded mast step and lower end of the mast which led to the above described fix.

Thanks for the invite to see your boat. The same invitation holds for you if you plan to go to Anacortes. We should try to coordinate something. We shouldn't let all those boats in the Bay Area have all of the socializing. Maybe we can meet in the San Juans.

Thanks again for your comments, Steve.

John Isakson (jisakson@whidbey.net)

From:

Thomas Wall snowflower@compuserve.com

Date: 07/28/99 04:59:21 PM GMT

John,

The spreaders on Snowflower have a "lucite" spacer (editorís note: most likely delrin), probably 1" deep with (I think) a rabbet to fit into the end of the spreader, and a groove to hold the shrouds in place that separates the stainless steel from the aluminum.

When we had the standing replaced a couple of years ago the rigger commented on what a good idea these were, though he didn't mention any problem with our spreader tips at the time.

If new spreaders are the only answer. Check with Kenyon about replacements. They might still have them available.

Ref the mast step: if and when you pull the mast, when it is re-stepped, be sure that the yard puts a piece (+/- 6"x8" to cover the entire base of the mast) of some sort of hard dielectric material between the mast and the step. You might also spray into the electric cable hole after the mast is stepped a "ton" of Lanacote to protect the interior of the mast from any moisture that might accumulate down in there.

Hope you get your problems taken care of easily.

Skipper Wall

From:

Mark Wyatt MarkBWyatt@compuserve.com

Date: 07/30/99 03:50:19 AM GMT

Subject:

RE: Spreaders

If you have an early Islander with the LeFeill mast, the solution to cracked spreaders is to buy new ones from LeFeill. They're fairly inexpensive ($120 a set), and if you send them your broken ones they'll drill the holes for the clevis pins for you.

From:

John Isakson jisakson@whidbey.net

Date: 07/31/99 02:33:28 AM GMT

Subject:

Spreaders Finished

Hi Rick,

My Spreader project is finished, except for re-tuning the standing rigging. I'll do that tomorrow. I took some photographs of the end fittings that I built. If the photos come out ok (I am a bad, really bad, photographer) I will mail you a package of the photos and the drawings that I made. They may give others an idea or encouragement about replacing spreader end fittings.

This picture shows the new plug fittings; the left one disassembled; the right one assembled.

New ends in place.

Two coats of synthetic Chromate primer, plus two coats of clear lacquer for protection.

John Isakson